Your cart is currently empty!

Revolutionizing Precision: The Versatile Applications of a Small CNC Machine

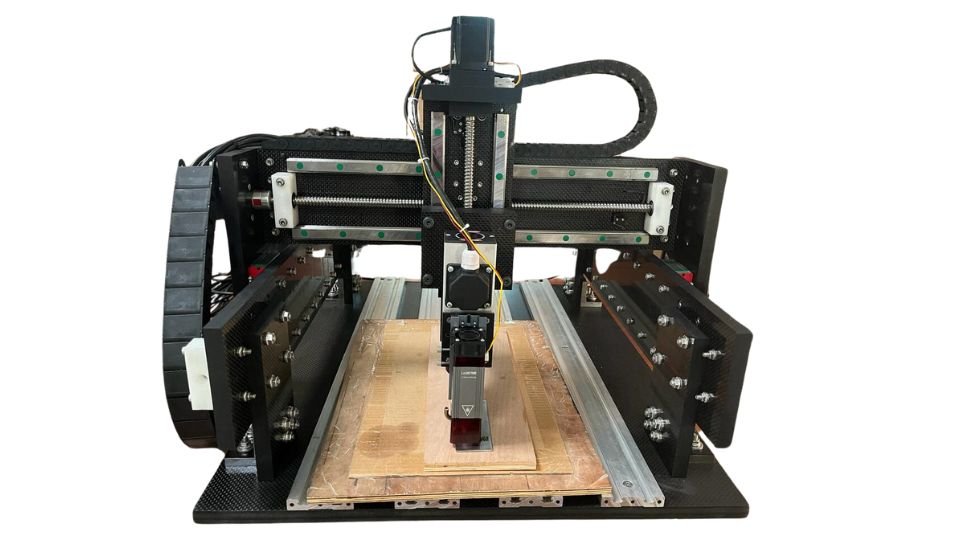

In today’s rapidly evolving technological landscape, the demand for precision engineering tools like the small CNC machine has skyrocketed. Small industries, scientific institutions, research and development centers, aerospace, biotech, and many other specialized sectors are increasingly relying on these compact, yet powerful, tools for a wide range of applications. The small CNC machine stands out not only for its ability to deliver high-accuracy machining but also for its versatility, portability, and cost-effectiveness. Particularly, Akriti Precision Systems (Bangalore) has set a new standard with their CXC3 Meteor and CXC3 Majestic Series, the latter offering an advanced 4th axis option for even more complex tasks.

1. Small CNC Machines in Small Industries

Small industries, including custom manufacturing shops, are turning to small CNC machines for their ability to deliver precise parts with minimal human intervention. These machines can handle a variety of materials, from metals to plastics, making them ideal for creating small batches of custom components. The compact design of the small CNC machine allows these industries to optimize their workspace, ensuring maximum efficiency even in limited areas.

The CXC3 Meteor from Akriti Precision Systems is particularly favored in this sector due to its user-friendly interface and high precision capabilities. It provides small businesses with the ability to produce high-quality parts in-house, reducing dependence on third-party suppliers and shortening production cycles.

2. Scientific Institutions and Their Precision Demands

Scientific institutions often require tools that can deliver extreme precision for experimental setups and prototyping. Here, the small CNC machine shines, enabling researchers to fabricate intricate parts with tolerances within microns. These machines are essential for creating custom laboratory equipment, precise mounting fixtures, and other specialized components necessary for cutting-edge research.

The CXC3 Majestic Series from Akriti Precision Systems, equipped with a 4th axis option, stands out in this field. The additional axis allows for the machining of complex geometries and the creation of parts that would be impossible with a standard three-axis CNC machine. This feature is crucial for institutions where the fabrication of multi-faceted components is a routine requirement.

3. Research and Development: Prototyping and Innovation

Research and development (R&D) departments across various industries rely heavily on prototyping as part of the innovation process. The ability to quickly iterate designs and produce prototypes is crucial for the success of R&D projects. A small CNC machine offers the perfect solution, allowing teams to quickly manufacture prototype components, test their designs, and make necessary adjustments without long delays.

The CXC3 Meteor is often the go-to choice for R&D teams due to its reliability and ease of use. Its precision and speed allow researchers to produce prototypes that closely match their final designs, facilitating smoother transitions from concept to product.

4. Aerospace: Precision in the Skies

Aerospace engineering demands the highest levels of precision, where even the smallest error can lead to catastrophic failures. Small CNC machines are invaluable in this sector, used for producing everything from small engine components to intricate parts of avionics systems. These machines can handle high-performance materials like titanium and Inconel, which are commonly used in aerospace applications.

Akriti Precision Systems’ CXC3 Majestic Series, with its 4th axis capability, is particularly suitable for aerospace applications. The additional axis provides the ability to machine complex parts, such as turbine blades and aerodynamic surfaces, which require precise multi-angle machining. This capability ensures that aerospace engineers can produce components that meet the stringent standards of the industry.

5. Biotech: Tailoring Solutions for Medical Innovations

In the biotech industry, the need for customized medical devices, implants, and research tools is ever-growing. A small CNC machine plays a pivotal role in this sector by enabling the creation of bespoke components tailored to specific patient needs or research requirements. Precision is critical, especially when producing parts for medical devices that must adhere to strict safety and performance regulations.

The CXC3 Meteor, with its superior accuracy and fine detailing capabilities, is a favored tool in the biotech sector. It allows for the production of small, intricate components, such as microfluidic devices or custom implants, with the precision required for medical applications. The CXC3 Majestic Series, offering the flexibility of a 4th axis, can tackle even more complex geometries, essential for cutting-edge biotech innovations.

6. Specialized Applications in Various Fields

Beyond the primary industries, small CNC machines find use in many specialized applications that require precise, small-scale machining. For instance, in the jewelry industry, these machines are used to create intricate designs and engravings on precious metals. In the watchmaking industry, small CNC machines are indispensable for producing the tiny, precise components required for high-end timepieces.

Akriti Precision Systems’ CXC3 Meteor is especially popular in these fields for its ability to deliver fine detail and high-quality finishes. Its ease of operation allows craftsmen to focus on creativity while the machine handles the technical precision required.

7. The Role of Small CNC Machines in Educational Institutions

Educational institutions, particularly those with engineering and technical programs, benefit greatly from incorporating small CNC machines into their curricula. These machines provide students with hands-on experience in machining and manufacturing, preparing them for careers in industries where precision engineering is key.

The CXC3 Meteor and CXC3 Majestic Series from Akriti Precision Systems are ideal for educational settings. Their user-friendly interfaces make them accessible to students, while their high precision ensures that educational projects meet professional standards. The 4th axis option available in the Majestic Series also introduces students to more advanced manufacturing techniques, giving them a competitive edge in the job market.

8. Advancements in Automation and Small CNC Machines

As automation becomes increasingly integrated into manufacturing, small CNC machines are playing a crucial role in this transformation. The ability to automate repetitive tasks with high precision not only increases efficiency but also reduces the potential for human error. Small CNC machines are now being equipped with advanced software and sensors that allow for greater control and adaptability in automated processes.

Akriti Precision Systems has been at the forefront of integrating automation features into their CNC machines. The CXC3 Meteor and Majestic Series both feature advanced control systems that allow for seamless integration into automated production lines, making them ideal for industries looking to enhance their manufacturing processes.

9. Customization Capabilities of Small CNC Machines

One of the most significant advantages of small CNC machines is their ability to produce highly customized parts. Whether it’s a unique prototype, a specialized component, or a personalized item, these machines can deliver precise, made-to-order products. This capability is invaluable in industries where customization is key, such as in the production of custom-fit medical devices or personalized consumer goods.

The CXC3 Majestic Series, with its 4th axis option, offers unparalleled customization capabilities. The additional axis allows for machining complex parts that require multi-angle operations, expanding the possibilities for customization. This makes the Majestic Series an excellent choice for industries that need to produce highly specialized components.

10. Precision and Versatility: The Future of Small CNC Machines

Looking forward, the role of small CNC machines in various industries is set to expand as technology continues to evolve. These machines will become even more integral to manufacturing, research, and development as they offer the perfect balance of precision, versatility, and affordability. Companies like Akriti Precision Systems are leading the way with innovations that enhance the capabilities of small CNC machines, ensuring they meet the ever-increasing demands of modern industries.

FAQs

1. What industries benefit the most from using small CNC machines?

Small CNC machines are highly beneficial in industries such as aerospace, biotech, small-scale manufacturing, research and development, and specialized fields like jewelry and watchmaking.

2. What makes Akriti Precision Systems’ CNC machines stand out?

Akriti Precision Systems’ CXC3 Meteor and CXC3 Majestic Series stand out for their precision, ease of use, and advanced features such as the 4th axis option in the Majestic Series, which allows for more complex machining tasks.

3. How do small CNC machines contribute to research and development?

Small CNC machines enable rapid prototyping and the production of precise components, which are essential for testing and iterating designs in research and development settings.

4. What are the advantages of using a small CNC machine in the biotech industry?

In the biotech industry, small CNC machines allow for the creation of custom medical devices and research tools with the precision necessary to meet strict industry standards.

5. Can small CNC machines handle complex geometries?

Yes, especially with options like the 4th axis available in Akriti Precision Systems’ CXC3 Majestic Series, which allows for the machining of intricate and complex parts.

6. Are small CNC machines suitable for educational purposes?

Absolutely. Small CNC machines like the CXC3 Meteor and Majestic Series are excellent for educational institutions, offering students hands-on experience with professional-grade tools.

Conclusion

In conclusion, the small CNC machine is a versatile tool with a broad range of applications across various industries, from small-scale manufacturing to advanced scientific research. Akriti Precision Systems, with their CXC3 Meteor and CXC3 Majestic Series, provides solutions that meet the precise needs of these diverse fields. Whether it’s producing intricate components for aerospace or custom parts for biotech, these machines deliver the accuracy and reliability that modern industries demand. As technology continues to advance, the role of small CNC machines will undoubtedly grow, further cementing their place in the future of precision engineering.

A 2-in-1 Small CNC Machine from Akriti Precision Systems, a spindle and an optical laser system.