Your cart is currently empty!

Profitable Small Business Ideas using CNC Machines for Brass and Aluminum Work

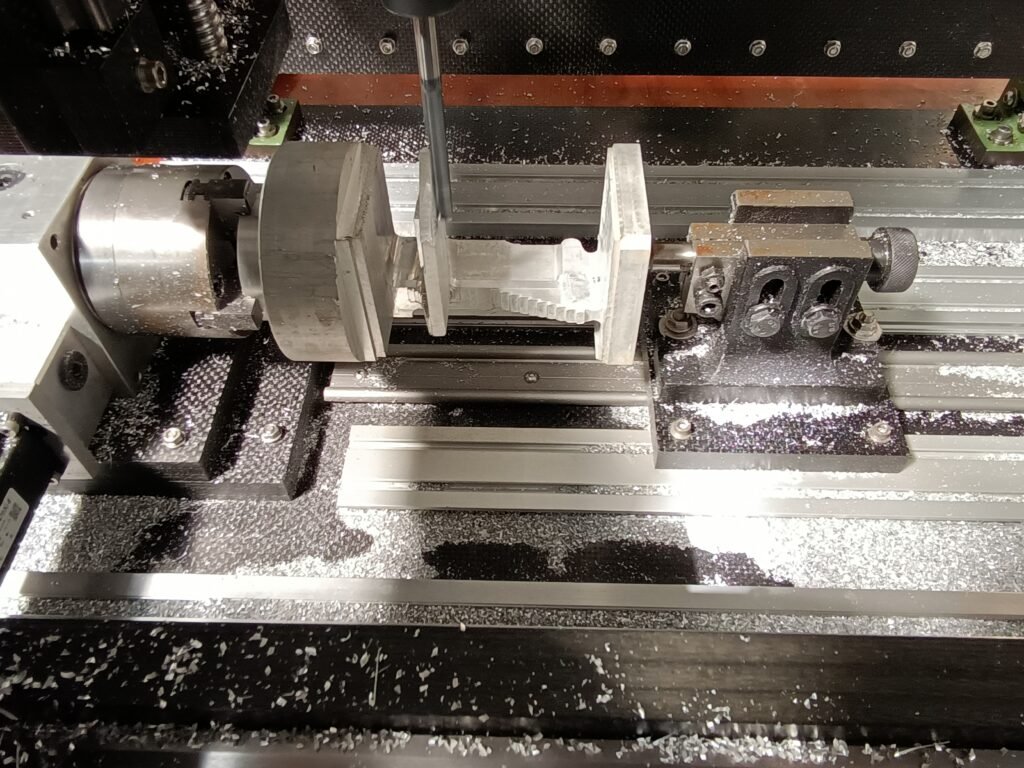

The world of precision engineering and manufacturing is constantly evolving, with CNC (Computer Numerical Control) machines becoming an essential tool for creating high-quality products from materials such as brass and aluminum. For entrepreneurs looking to start a business, CNC machines offer incredible versatility and profitability. In this article, we will explore several profitable small business ideas using CNC machines, focusing on the powerful CXC3 Majestic and CXC3 Majestic XL models from Akriti Precision Systems, a leading CNC machine manufacturer based in Bangalore, India.

These machines have gained significant attention not just because they are made in India, but because of their exceptional quality. Approximately 75% of the parts for these machines are manufactured locally, while the rest are sourced from renowned companies in Italy, Germany, Japan, Taiwan, Korea, and France. This thoughtful blend of domestic manufacturing and high-quality foreign parts ensures these machines deliver unmatched performance and durability, making them perfect for small businesses.

The Importance of Quality Parts in CNC Machines

One of the primary reasons CNC machines are so effective in manufacturing is the precision they offer. To achieve such precision consistently, the quality of parts used in the machine itself is critical. The CXC3 Majestic and CXC3 Majestic XL, with their carefully sourced components, demonstrate how important it is to maintain high standards in production. By using durable parts from reliable sources, these machines can operate smoothly for years with minimal maintenance, reducing downtime and increasing productivity for businesses.

Components from Italy, Germany, Japan, and other countries are chosen for their reliability and precision, ensuring the machine’s performance is stable. This combination of local production and quality-conscious sourcing results in machines that stand the test of time and deliver outstanding results in various applications, such as brass and aluminum work. The importance of sourcing quality parts can’t be overstated, especially for businesses that depend on consistent, high-quality output to meet client demands.

Profitable Small Business Ideas Using CNC Machines

CNC machines open up numerous avenues for entrepreneurs, especially when it comes to working with brass and aluminum. Let’s explore some of the best small business ideas using CNC machines that can help you generate profit.

1. Custom Metal Signage

Creating custom metal signage using CNC machines is a growing business with high demand. Brass and aluminum are ideal materials for crafting durable, aesthetically pleasing signs for businesses, homes, or offices. With a CNC machine like the CXC3 Majestic, you can design intricate logos, fonts, and decorative elements with ease, offering personalized products to customers.

2. Automotive Parts Manufacturing

The automotive industry relies heavily on CNC-machined parts made from materials like aluminum due to their strength and lightweight nature. Small businesses can manufacture high-quality automotive components such as engine brackets, exhaust systems, and gearboxes. The precision of the CXC3 Majestic XL allows businesses to meet the strict tolerances required in this industry, providing parts that are both reliable and durable.

3. Jewelry and Artistic Brass Creations

Brass is a popular material for crafting jewelry and art pieces, and CNC machines provide the precision needed for delicate designs. Entrepreneurs can produce custom jewelry, such as rings, bracelets, and pendants, or even home décor items. By offering personalized creations, small businesses can attract a niche market of customers looking for unique and intricate brass products.

4. Precision Engineering Components

For businesses specializing in high-precision components, CNC machines are indispensable. The ability of the CXC3 Majestic to manufacture complex parts with tight tolerances means that small businesses can supply various industries, including aerospace, medical devices, and electronics. High-quality aluminum and brass components are often in demand for these industries, and businesses using CNC machines can quickly meet those needs.

5. Prototyping Services

Many industries require prototypes to test new products before full-scale production. CNC machines allow small businesses to offer rapid prototyping services, providing clients with accurate and functional prototypes made from aluminum or brass. This service is in high demand in fields like consumer electronics, engineering, and automotive design, making it one of the most lucrative small business ideas using CNC machines.

6. Home Hardware Manufacturing

Manufacturing home hardware such as door handles, hinges, and knobs from brass or aluminum is another excellent business idea. These items are always in demand due to the durability and aesthetic appeal of both metals. The precision of the CXC3 Majestic XL ensures the production of high-quality, uniform hardware that meets both functional and aesthetic requirements.

7. Musical Instrument Components

Brass is commonly used in the production of musical instruments like trumpets, saxophones, and tubas. With the intricate design capabilities of CNC machines, small businesses can manufacture not only instruments but also high-quality replacement parts for these instruments, catering to a global market of musicians.

CXC3 Majestic & CXC3 Majestic XL: Game-Changers for Small Businesses

Akriti Precision Systems, based in Bangalore, India, has designed the CXC3 Majestic and CXC3 Majestic XL with the needs of small to medium-sized businesses in mind. These CNC machines are perfect for brass and aluminum work, offering both precision and speed.

The CXC3 Majestic is compact yet powerful, ideal for small workshops that require versatile machines capable of handling a range of materials and projects. On the other hand, the CXC3 Majestic XL offers more power and larger workspace, making it suitable for businesses with high-volume production requirements. Both models are engineered to the highest standards, utilizing the best available technology to ensure reliable, long-lasting performance.

Why Choose Akriti Precision Systems’ CNC Machines?

Starting a small business with CNC machines involves significant investment in equipment, so it’s important to choose machines that are reliable, cost-effective, and high-performing. The CXC3 Majestic and CXC3 Majestic XL stand out for several reasons:

Support and Service: Akriti Precision Systems provides excellent customer service, ensuring that small businesses can get the support they need when they need it. This includes training, troubleshooting, and maintenance services, making the machines easier to use and more reliable in the long run.

Made in India with Global Standards: With 75% of the parts manufactured locally, these machines support the “Make in India” initiative while maintaining high international standards. The remaining components are sourced from quality-conscious suppliers in countries like Germany and Japan, ensuring superior performance.

Versatility and Precision: These machines are designed to handle both small and large projects with precision, making them ideal for businesses that need flexibility in their production processes.

Cost-Effective Solution: While CNC machines from international brands can be prohibitively expensive, the CXC3 Majestic series offers a more affordable option without sacrificing quality. This allows small business owners to invest in high-end technology without overstretching their budget.

Conclusion

For entrepreneurs looking to dive into manufacturing, CNC machines are an incredible asset. The CXC3 Majestic and CXC3 Majestic XL, manufactured by Akriti Precision Systems, provide the performance, precision, and durability needed to start a successful business. With these machines, you can explore various small business ideas using CNC machines, from custom signage to automotive parts, jewelry, and precision engineering. These ideas not only tap into growing markets but also allow for creative, high-quality products that customers will love.

If you’re considering entering the world of CNC machining, the first step is selecting a machine that can handle your business’s needs. Akriti Precision Systems’ focus on quality, with 75% of parts made in India and others sourced from top global manufacturers, guarantees that you’ll have the right tools to succeed. The reliability and efficiency of these machines make them a perfect foundation for any business working with brass and aluminum.