Your cart is currently empty!

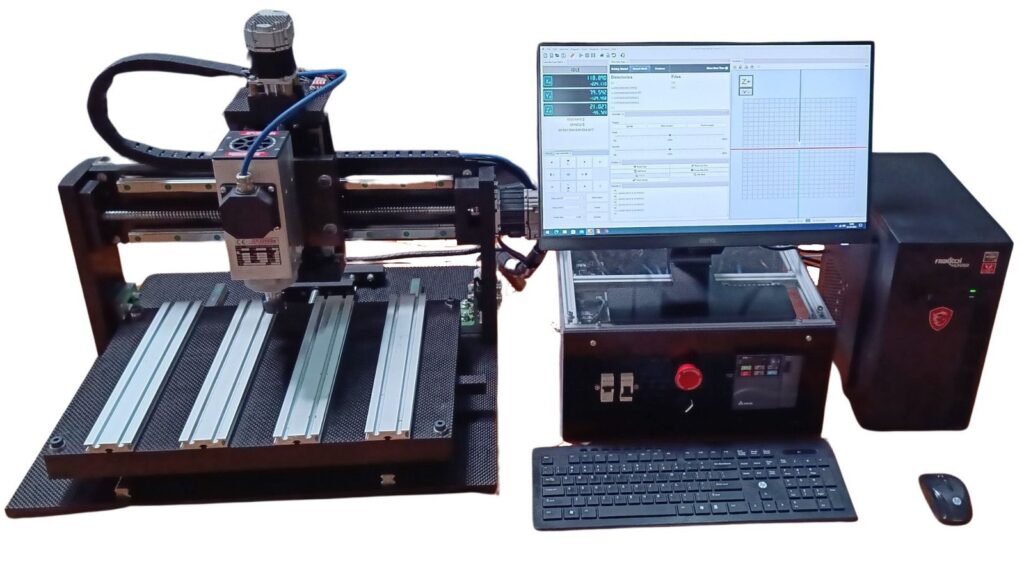

High Precision 3 & 4 Axis CNC Machines for Prototyping: Revolutionizing Design Studios and R&D Labs

In today’s competitive landscape, where innovation is paramount, the demand for precise and reliable prototyping equipment has never been greater. Design studios and research & development (R&D) labs require tools that offer high accuracy, versatility, and continuous operation to keep up with the fast-paced world of product development. Akriti Precision Systems, based in Bangalore, offers a cutting-edge solution with their high precision 3 & 4 axis CNC machines, specifically engineered for these environments. With a repeat positioning accuracy of up to 3.5 microns and sub-micron positioning capability, these cnc machines for design studios and R&D Labs are setting new benchmarks in the industry.

What is a CNC Machine? Understanding the Basics

A CNC machine (Computer Numerical Control machine) is a sophisticated piece of equipment used in the manufacturing process to precisely control machinery tools via a computer. These machines can perform a variety of functions, including cutting, milling, drilling, and engraving, among others, making them indispensable in the production of prototypes and parts. The CNC machine full form highlights its core function: leveraging computer technology to automate and enhance the precision of mechanical processes.

The Role of High Precision CNC Machines in Prototyping

Prototyping is a critical stage in product development, where design ideas are turned into tangible models for testing and evaluation. The accuracy of these prototypes can significantly influence the success of the final product. Akriti Precision Systems’ CNC machines are designed to meet the high standards required by design studios and R&D labs. The 3 & 4 axis configurations allow for intricate and complex geometries to be machined with utmost precision, ensuring that every prototype closely matches the design specifications.

Key Features:

- Up to 3.5 Micron Repeat Positioning Accuracy: Ensures that each part is machined with consistent precision, crucial for prototyping.

- Sub-Micron Positioning Capability: Offers the ability to perform ultra-fine machining tasks, essential for advanced R&D applications.

- Customizable for Various Environments: Adaptable to different working conditions, making it ideal for diverse industrial needs.

- Continuous 24/7 Operation: Capable of handling rigorous production schedules without compromising on performance or accuracy.

Why Choose Akriti Precision Systems’ CNC Machines?

Akriti Precision Systems is committed to delivering not just machines, but solutions that drive innovation in design and manufacturing. Their CNC machines stand out for several reasons:

- Exhaustive Warranty Options and Support: Akriti Precision Systems understands the importance of reliability and offers comprehensive warranty options, ensuring peace of mind for their clients. Their dedicated support team is always ready to assist with any issues, ensuring minimal downtime.

- Customizability: Every design studio and R&D lab has unique needs. Akriti’s CNC machines can be customized to fit specific requirements, whether it’s the working environment, material types, or operational demands.

- Scalability: These machines are not just for prototyping. Their robust design and precision make them fully capable of handling continuous production runs, enabling a smooth transition from prototype to production without the need for new equipment.

CNC Machine Types: Understanding 3 & 4 Axis Machines

CNC machines come in various configurations, but the 3 and 4 axis machines are particularly popular for their balance of versatility and precision.

- 3 Axis CNC Machines: These machines operate on the X, Y, and Z axes, allowing for the machining of flat surfaces and simple shapes. They are ideal for straightforward tasks such as cutting and drilling.

- 4 Axis CNC Machines: In addition to the X, Y, and Z axes, 4 axis machines include rotation around the X axis, which is known as the A axis. This added capability allows for more complex shapes to be machined, such as cylindrical parts and parts with intricate curves.

CNC Machine G Codes and M Codes: The Language of Precision

To fully leverage the capabilities of a CNC machine, understanding CNC machine G codes and M codes is crucial. G codes control the movement and operation of the CNC machine, dictating actions such as positioning and cutting paths. CNC machine M code list complements G codes by handling auxiliary functions like turning the spindle on or off or changing tools. Mastery of these codes is essential for CNC machine operators to program precise machining tasks effectively.

The Cost of Precision: CNC Machine Price in India

Investing in a high-precision CNC machine can be significant, but it’s a crucial step for any design studio or R&D lab aiming to stay ahead in innovation. The CNC machine price in India varies depending on the machine’s capabilities, customization options, and brand reputation. Akriti Precision Systems offers competitive pricing for their state-of-the-art machines, ensuring that businesses of all sizes can afford the best tools for their prototyping needs.

Empowering Operators: CNC Machine Programming Course

Operating a CNC machine requires skill and knowledge. Akriti Precision Systems not only provides advanced machinery but also provides training to cover machine operation, conversion from . These courses cover everything from the basics of machine operation to advanced programming techniques, ensuring that operators can fully exploit the capabilities of the machines.

Applications Beyond Prototyping

While these CNC machines are indispensable for prototyping, their applications extend far beyond. Akriti Precision Systems’ CNC machines can also be used for:

- CNC Machine Laser Cutting: Precision cutting of materials using laser technology.

- CNC Machine Router: Perfect for woodworking and engraving tasks.

- 4 Axis CNC Machine : Essential for creating cylindrical parts.

- CNC Machine Wood Carving: Ideal for intricate designs in wood.

The Future of Prototyping with Akriti Precision Systems

As the industry continues to evolve, the demand for precision, speed, and reliability in prototyping will only increase. Akriti Precision Systems is at the forefront of this evolution, offering CNC machines that not only meet the current demands but are also adaptable to future challenges. With their focus on high precision, customization, and continuous operation, Akriti’s CNC machines are set to revolutionize the way design studios and R&D labs approach prototyping.

Conclusion

In a world where the smallest details can make the biggest difference, having the right tools is essential. Akriti Precision Systems’ 3 & 4 axis CNC machines provide the precision, reliability, and support needed to turn innovative ideas into reality. Whether you’re in a design studio or an R&D lab, these machines are the perfect companion for pushing the boundaries of what’s possible.

Frequently Asked Questions (FAQs)

1. What does CNC stand for?

CNC stands for Computer Numerical Control, a technology that automates the control of machining tools using computer programming.

2. How accurate are Akriti Precision Systems’ CNC machines?

These machines offer up to 3.5 micron repeat positioning accuracy and sub-micron positioning capability, making them ideal for high-precision tasks.

3. What is the price range of CNC machines in India?

The price of CNC machines in India varies based on specifications and customization. Akriti Precision Systems offers competitive pricing for their high-precision machines.

4. Can these CNC machines operate 24/7?

Yes, Akriti Precision Systems’ CNC machines are designed for continuous operation, capable of running 24/7 without compromising performance.

5. What is the difference between G codes and M codes in CNC machining?

G codes control the movement and operation of the machine, while M codes manage auxiliary functions such as tool changes and spindle control.

6. Are there training programs available for operating these CNC machines?

Yes, Akriti Precision Systems provides comprehensive CNC machine programming courses to ensure operators are well-equipped to handle advanced machining tasks.

7. Which models can be customized for high and extreme precision work?

The CXC3 PCBPrecision Pro & PCBPrecision Pro XL series of CNC machines are most suited for these applications and are highly customizable for your respective environment.